AF, AG, and AR coatings are common surface treatment technologies used in products like glass covers. Each has unique characteristics and applications, but they can sometimes be confused. Below, we'll explore the differences between these three coating technologies in depth, helping you not only understand them but also easily distinguish them in practical applications.

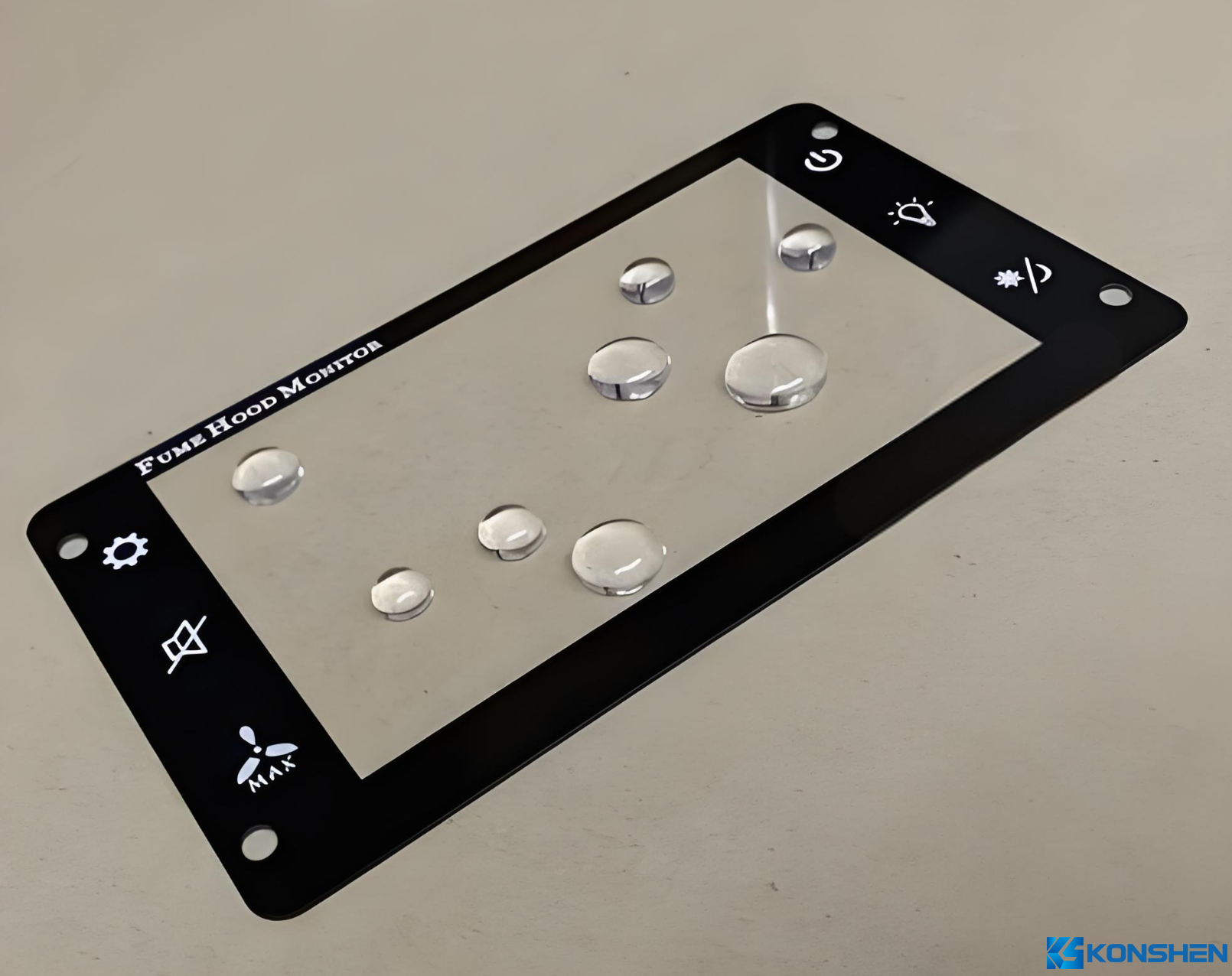

AF coating, also known as anti-fingerprint coating, operates on the principle of the lotus leaf's self-cleaning effect. This technology involves covering the glass surface with a nanoscale chemical material, which significantly reduces the glass's surface tension. As a result, the contact area between dust and the glass is reduced by up to 90%, endowing the glass with strong water repellency, oil resistance, and anti-fingerprint properties. Additionally, this technology ensures that video glass panels maintain their bright and clean appearance over the long term.

|

1.1 Efficacy:Effectively removes dirt, fingerprints, and oil stains from touchscreens, leaving the screen looking brand new. The treated touchscreen surface becomes smoother, with a significantly improved feel, enhancing the user's operating experience. |

This coating technology is widely used in display glass covers for various touchscreens, especially single-sided AF coating, which is specifically designed for the front side of glass.

Offers multiple processing options, such as combinations like AG+AF, AR+AF, and AG+AR+AF, to meet different customer needs.

Next, we'll detail the process flow of anti-fingerprint treatment:

Cleaning → Drying → Coating → Curing → High-temperature Tempering

First, in the pre-treatment stage, mild alkaline cleaners or solvents are used to remove oil, moisture, and other contaminants from the substrate surface, often combined with ultrasonic cleaning for better results.

Then, AF solution is evenly applied to the product surface to form a protective film.

Subsequently, the sprayed glass is taken out and baked in an oven at 120°C for 30 minutes (adjusted based on product characteristics and requirements for optimal results).

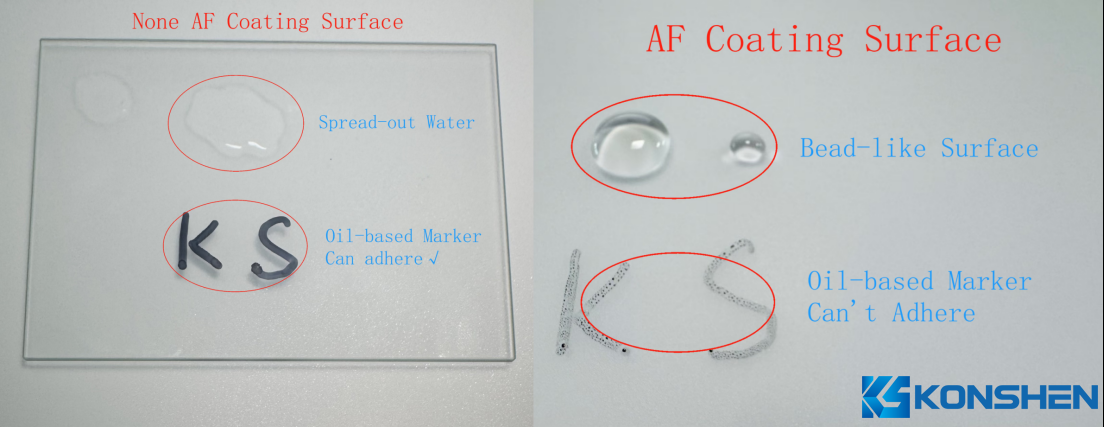

Drop a water droplet on the surface. If the droplet rolls freely, the surface has an AF coating.

Try drawing a line on the surface with an oil-based marker. If no marks can be made, it also indicates the presence of an AF coating.

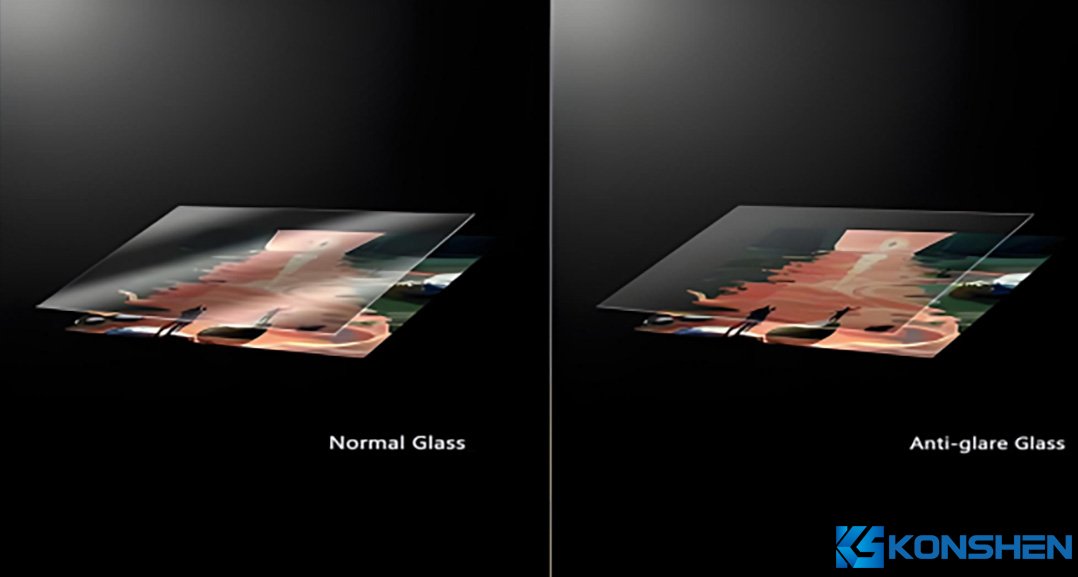

AG coating, also known as anti-glare coating, is a technology used to reduce light reflection. Its principle is to cover the surface of optical components such as glass or plastic with a special coating to reduce specular reflectivity, thereby improving the light transmittance of optical components and visual comfort. This technology is widely applied in various optical devices, such as display screens and telescope lenses, aiming to reduce glare interference and enhance users' experience.

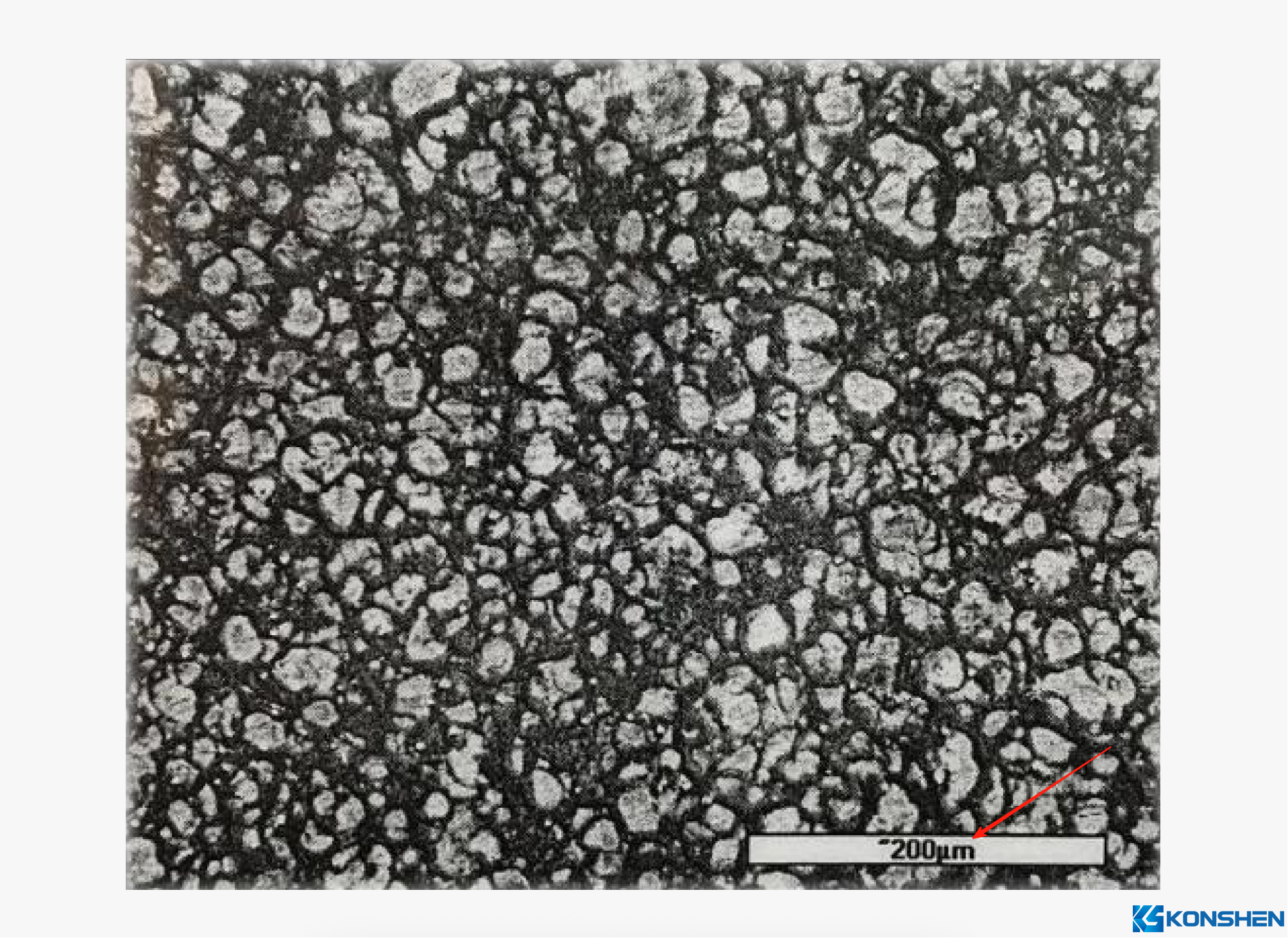

Anti-glare glass, also known as AG glass, is a type of glass where the originally smooth and reflective surface is transformed into a matte state (i.e., the surface presents a rough, granular texture) through chemical etching or spraying methods. This treatment changes the surface roughness of the glass, thereby achieving a diffuse reflection effect and effectively reducing light reflection. Such glass is widely used in various optical devices to reduce glare interference and improve users' experience.

Microscopic view of the AG glass surface

Through the scattering and diffuse reflection of light, anti-glare glass effectively reduces light reflection, thereby minimizing glare and glare-induced discomfort. It creates a clear and transparent visual space for users, enhancing visual enjoyment. The basic characteristics of anti-glare glass have been introduced in detail in the previous article.

When light is reflected on anti-glare glass, it forms diffuse reflection, reducing the glare of light and providing viewers with a better visual experience. The lower the glossiness, the better the diffusion effect, and the less impact from external glare. In addition, anti-glare glass is available in single-sided and double-sided types, and the AG-treated side should be facing upward during use.

Anti-glare glass is widely used in outdoor displays or displays under strong light, such as advertising screens, ATM machines, POS cash registers, and medical B-ultrasound displays. It is also commonly used in e-book readers, gas station displays, subway ticket checking machines, etc.

Place a piece of glass under a fluorescent lamp and observe the lamp tube from the front. If the light source of the lamp tube is scattered, that side is the AG-treated side; if the light source is clearly visible, that side is the non-AG side. This is the most intuitive way to distinguish from the visual effect.

AR coating, also refer to anti-reflective coating, is an optical thin film that can increase light transmittance and reduce light reflection through its special physical and chemical properties. This technology is widely used in various optical products, such as eyeglass lenses and display screens, aiming to provide a clearer and more comfortable visual experience.

|

AR coating is a method that reduces glass reflectivity and improves transmittance through optical coating technology. After special treatment, both single-sided and double-sided glass can achieve this effect, with transmittance increased to over 99% and reflectance reduced to below 1%. Its principle lies in the fact that when light travels from an optically thinner medium to an optically denser medium, half-wave loss occurs. |

By improving the transmittance of glass, AR coating makes display content more clearly visible, bringing viewers a more comfortable and clear visual experience.

AR coating is widely used in high-definition displays, photo frames, cameras, and optical components of various display glass panels.

Place a piece of ordinary glass and a piece of AR glass side by side, closely against a computer screen or other printed images. The image seen through the AR glass will be much clearer.

The surface of AR glass can be further treated with AG (anti-glare) technology to enhance its optical performance.

AF, AG, and AR coatings play a vital role in enhancing the functionality and user experience of glass covers across different industries. While AF coatings offer superior resistance to fingerprints and oils, AG coatings focus on reducing glare for improved visibility, and AR coatings enhance light transmittance to deliver clear, vibrant displays.

Understanding these differences helps designers choose the most appropriate solution based on application needs, whether it's for consumer electronics, automotive displays, or professional optical equipment. By selecting the right coating or combining multiple coatings,products can achieve optimal durability, visual performance, and user satisfaction.

Ready to take your glass project to the next level? Contact us today to discuss your custom glass needs and get a quote!

contact us